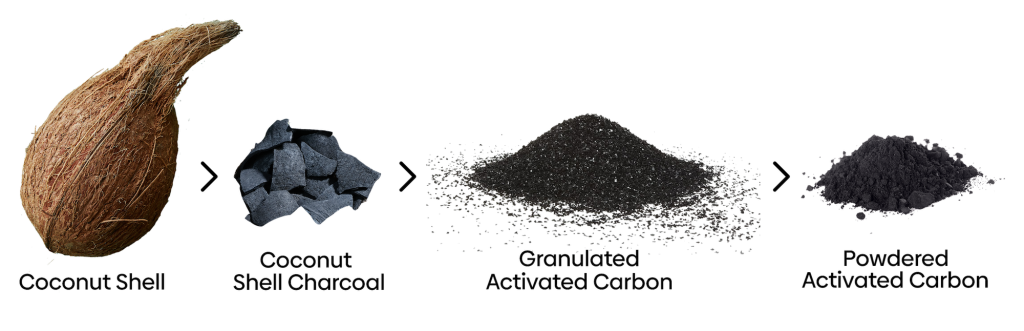

How Is Coconut Shell Activated Carbon Made

Making coconut-shell activated carbon isn't as difficult as you might think. Let's look at the three-step process of making coconut-shell activated carbon.

Step 1: Charring

The first step to making coconut-shell activated carbon is to ensure the used coconuts are cleaned and dried with the exterior fibers removed. After this has been done, the coconut shells need to go through the first stage, which is to char them.

To do this, they need to be subjected to very high temperatures, with the optimal temperature being between 500-600 degrees Celsius or 932-1,112 degrees Fahrenheit for many hours. Eventually (usually within 12 hours), the coconut shells will become charcoal.

One of the most popular production methods for activated carbon occurs in a drum kiln with a chimney. Since it has a chimney, a drum kiln can effectively create higher interior temperatures by limiting oxygen flow. Often the coconut shells at the bottom of the drum kiln will carbonize first.

Step 2: Pacification

The next step in the coconut carbon activation process is pacification. Pacification means that the airflow is wholly cut off from the bottom of the drum kiln, which allows the coals to begin cooling. This process is crucial to developing coconut-shell activated carbon because if left burning indefinitely, the formed coal will turn to ash.

Step 3: Steam Activation

Once the coal is ready, the next step is to activate it to become a filter. The primary purpose of activating the coconut shell carbon is to increase its pore size to catch more contaminants and particles when used for filtering.

There are primarily two ways to activate coconut shell carbon - by soaking it in chemicals like phosphoric acid, or it can be activated by steam, as mentioned previously.

For steaming, the temperature inside the rotary kiln must be brought to around 1,470-2,010 degrees Fahrenheit. This scorching steam will dehydrate the carbon, which allows the level of volatile organic compounds (VOCs) within it to be reduced.

While the coconut carbon is steamed, its pores will enlarge until they become large enough to catch molecules in water.

If you are looking to find a reliable supplier of Activated Carbon products, then Lvyuan can put you right. Get in touch with us.