Polyaluminium Chloride Safety Information

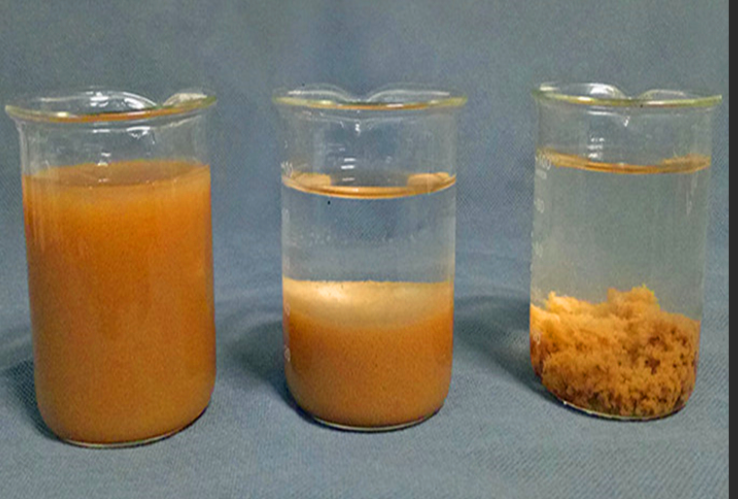

I. In operation, the water purification process of polymerized aluminum ammonide is generally divided into three stages. The three stages are coagulation stage, flocculation stage and sedimentation stage.

In the coagulation stage, when the liquid is injected into the coagulation vessel and the raw water is coagulated rapidly, fine alum flowers will be formed in a very short time. At this time, the water becomes more turbidity, which requires the water flow to produce intense turbulence.

Then, polyaluminum chloride enters the flocculation stage, which is the process of alum growth and coarsing, requiring appropriate turbulence and sufficient residence time (10~15min). In the later stage, a large number of alum can be observed to gather and sink slowly, forming a clear surface layer.

When the flocculant is in the settling stage, it is the settling process of the flocculant in the settling tank, which requires slow water flow. In order to improve efficiency, inclined tube or plate settler is generally used. Daxing's coarse alum flowers are deposited at the bottom of the pool by the inclined tube (plate) wall baffle, and the upper layer of water is clarified water. The residual turbidity remained basically unchanged in the later stage.

II. Aluminum ammonia should be stored in a dry, moisture-proof, heat away place (<80℃ do not damage the packaging, the product can be stored for a long time).

III. Aluminum ammonide products must be dissolved before use, and corrosion resistant materials should be used in dissolving equipment and dosing facilities.

IV. The effective storage period of solid products is two years, and the solid products can still be used after moisture.